12,000’ lateral well produces 37.7 MMcf/d

Southwestern Energy (ticker: SWN) announced second quarter results today, showing net income of $224 million, or $0.45 per share. This result is substantially superior to the $620 million loss the company incurred in Q2 2016.

Southwestern produced 222 Bcfe this quarter, which exceeds first quarter production by 9%. This increase comes despite third-party gathering operational issues which are expected to be resolved later in 2017.

In the Marcellus Southwestern drilled a total of 24 wells, and brought 36 wells to sales. The company is utilizing increasingly long lateral wells in its operations, with higher completion intensity. For example, Southwestern recently drilled the Seymour 1H, a well with a lateral length of over 12,000 feet. This well was successfully drilled over 90% within the targeted interval, and delivered an IP rate of 37.7 MMcf/d. The company has also added about 140 MMcf/d of new takeaway capacity to its portfolio, for a reported average cost of $0.10 per Mcf.

Southwestern’s first Utica well continues to show strong productivity, with a flat current rate of over 15 MMcf/d and 2 Bcf in its six months of cumulative production.

Third-party difficulties

Like several other Appalachian operators, Southwestern’s operations have been hampered by difficulties experienced by third-party midstream operators. A gathering line in Susquehanna County was expected to come online in early 2017, but is now likely to become active in Q4. In addition, a third-party compressor station unexpectedly came offline in late June. This station will not be recommissioned until sometime in Q3. Southwestern reports that it has taken action to mitigate these interruptions, including using alternate transportation paths.

On the financial side, Southwestern reports that it retired the remaining $251 million in outstanding 2018 bonds, leaving only $40 million in near-term debt. This debt will be repaid on maturity in October 2017.

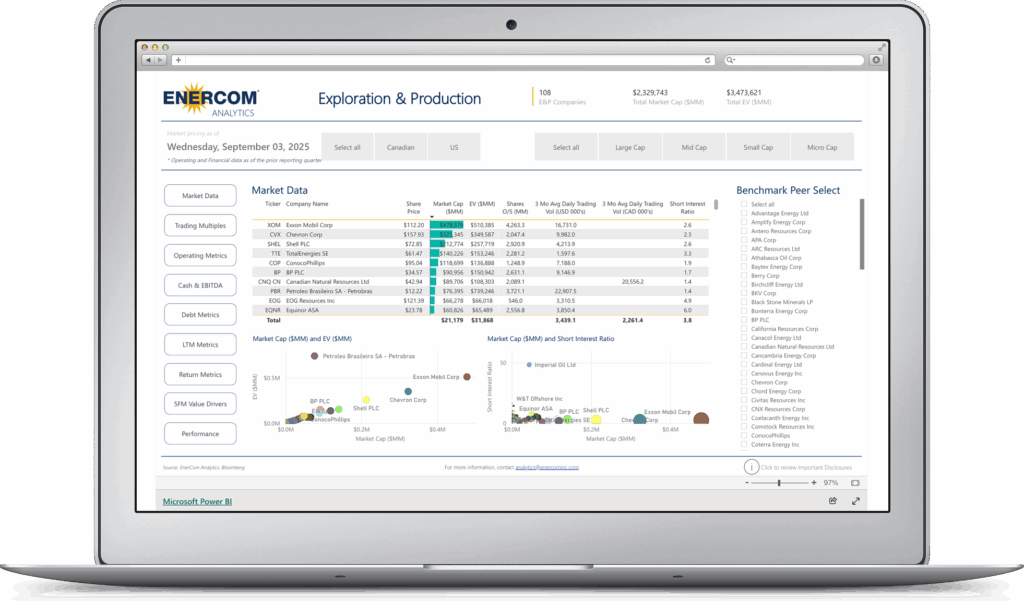

Southwestern will be a presenting company at the upcoming EnerCom conference in Denver, Colorado—The Oil & Gas Conference® 22.

The conference is EnerCom’s 22nd Denver-based oil and gas focused investor conference, bringing together publicly traded E&Ps and oilfield service and technology companies with institutional investors. The conference will be at the Denver Downtown Westin Hotel, August 13-17, 2017. To register for The Oil & Gas Conference® 22 please visit the conference website.

Q&A from SWN Q2 conference call

Q: You talked a little bit about some of the actions you took to mitigate some of the downtime in the Northeast. Could you give a little bit more color on exactly what you all are doing? And as we think of that, is this something that you have available, you feel comfortable that it’s going to be available to you going forward? And what’s the cost of these options?

William J. Way: Yeah, let me start with this, the slow pipeline jumper that we talked about. If you imagine going out into the extent of the gathering systems and looking at hydraulic opportunities for new – or for linking them together. So we’re not anywhere near a major trunk line. These are out in the gathering system. There was a delay in getting a permit. So the pipeline we be get – will get put on. It’s only a mile long or two miles long, so it’s not even a major trunk line.

That will get sorted, be done. Our gathering system has a number of tie-in points, if you look at that one alone. But if you look at our company, we’ve got gathering systems and capabilities all over the state. So you can – we can optimize and move things around. So that one-off gathering issue is there and be finished. There’s not anything holding that up.

The compressor station issue had to do with some vibration issues. But the station has been nearly completely rebuilt. They are working on the final pieces of equipment that have to do with pulsation and dampening. They’ll get that done. And the machines are set. The roof’s being put on. I mean it’s getting done.

So we also have flexible delivery from our network of marketing opportunities and firm transportation that enables us to move volume around, which enables us to again mitigate any issues with – from the gathering side going through that compressor station.

So again, a one-off issue, unfortunate for the company, the compressor company. But we’ve moved it around. The cost to mitigate all of this is really not a cost to mitigate. It’s shifting deliveries from one pipeline network to another to deal with the compressor issue. And moving around and seeing what further optimization we can have on our gathering system.

I think in the gathering system, it’s kind of actually a sort of a wake up to you that says, hey, are there further ways we can optimize this gathering system and optimize gas flows for the future as we get past all this? So as I said, not structural, not – it doesn’t change our development plan and the cost to us. We’ve not put any cost into it actually, except manpower time from our marketing team and our field folks.

Having said that, we have a great deal of marketing expertise – I mean gathering expertise. And we have that from the Fayetteville and from our Northeast presence. And we have joined together with our gathering company, the third-party gathering company, and are supporting the efforts to get this done. And part of that is helping accelerate schedules, et cetera. We look at these as cooperative efforts with all of our third-party suppliers.